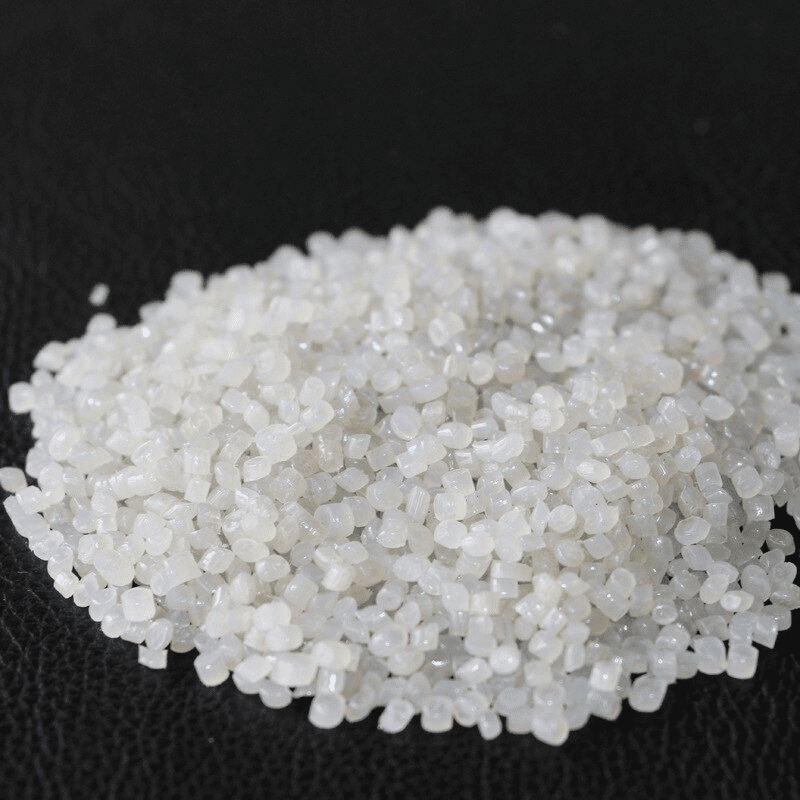

Polyethylene (polyethylene, PE for short) is a thermoplastic resin produced by polymerization of ethylene. In industry, it also includes copolymers of ethylene and a small amount of α-olefin. Polyethylene odorless, non-toxic, feel like wax, has excellent low-temperature resistance (the lowest use temperature up to -100 ~ -70 ° C), good chemical stability, resistance to most acids and alkalis (not resistant to oxidizing properties of the acid). It is insoluble in general solvents at room temperature, with small water absorption and excellent electric insulation.

Polyethylene is divided into high-density polyethylene (HDPE), low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE) according to the polymerization method, molecular weight and chain structure.

Polyethylene can be processed by general thermoplastic molding methods. Wide range of uses, mainly used in the manufacture of film, packaging materials, monofilament, daily necessities, pharmaceuticals and food packaging film, machinery parts, daily necessities, building materials, wire, cable insulation, coating, etc., and can be used as television, radar and other high-frequency insulating materials, industrial sizes of hollow containers, tubes, packaging calendering and ligature tape, rope and cable, fishing nets and woven fibers and so on.

HDPE cable material class

Polyethylene (polyethylene, PE for short) is a thermoplastic resin produced by polymerization of ethylene. In industry

Related products

- lldpe

LLDPE Shelter Film

- hdpe

HDPE drawing class

- homopolymerized pp

PP plastic powder class

- biodegradable plastic granules

LDPE general film type